- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

-

Description

This machine is designed on the basis of digesting and absorbing the same kind of equipment at home and abroad. It is a pellet can filling machine, mainly to meet the needs of more and more users in the tank filling small pellet solid to achieve automation. -

(Maize) Particle Filling

-

Description

Continuous spray sterilizer from Germany, Italy, Taiwan and other similar equipment technology from a new design. -

Spray sterilizer_Continuo

-

Description

All-round experiment kettle -

All-round experiment kett

-

Description

Cooking Jacked Kettle Stainless Steel Jacketed Kettle is also named vertical steam heating double-layer cauldron. Usually composed of pot and hold feet, and the pot is the double layer structure formed by inside and outside spherical pot; middle layer can add steam to steam. -

Cooking Jacked Kettle

-

Description

Double water bath rotary retort -

Double water bath rotary

-

Description

Vertical opening spray rotary retort -

Vertical opening spray ro

-

Description

RO static sterilizer -

RO static sterilizer

-

Description

Detection function: Cans deformation, the imperfect, foreign bodies, and inside of the body/foreign body inside the cans bottom or surface. Friendly interface, bad product processing method: pneumatic single segment automatically weed out. Maximum detection capability: 72000 BPH.Technical features: with independent intellectual property rights of the underlying algorithm, flexible meet the demand of all kinds of personalized detection; 360 degrees full range of testing technology innovation; Adjustable light source, to adapt to more product type; The design of the bottle type quickly switch; Rich production statistics and bad product storage, traces the function; Free custom detection module. -

Aluminum foil sealing and

-

Description

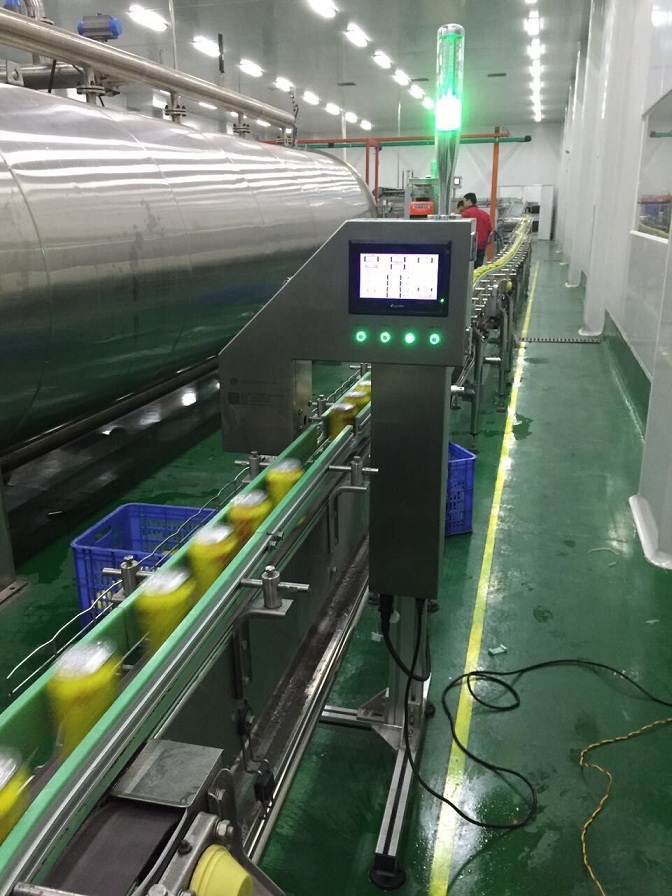

detector developed and produced by our company.By using the principle that the intensity of ray changes with the position of the material surface after the interaction between the low-energy photon source and the material under test, the filling liquid material capacity can be controlled.Because of its non-contact measurement method, it fundamentally solves the problem that the conventional weighing method cannot measure the filling liquid material capacity on the production line.Therefore widely used in food, medicine, chemical industry, weapons **** and other filling -

X-ray on-line liquid leve

-

Description

This detector r&d background against defects in conventional detector is developed, the traditional detection method is directly sticked to detect the internal pressure of tank, it will cause great waste, pot is discarded after testing, this detector USES the external pressure directly to obtain the internal pressure, does not destroy tanks, inspection qualified can return line directly, a day can save a lot of losses for the user. -

CNC non-destructive inter

-

Description

This machine is suitable for two pieces of aluminum cans, three pieces of iron cans, glass bottles and all other cladding containers, with simple and efficient operation -

Vacuum pressure detector

-

Description

Detailed introduction Equipment introduction :The machine is made up of the detection unit, man-machine interface, control unit, rejector, suitable for high speed PET bottled production line block level detection.Detection function: can be detected without cover, high cover, slanting cover, middle-east, ring defects, miscellaneous, liquid level detection, high level and low level, etc.Technical features: the professional image processing unit, which can realize the label 360 - degree detection. Concise in bottle design of lifting mechanism, through a simple manual regulation can quickly adapt to a variety of bottle type. Small test cabinet, minimize equipment cover an area of an area. Test running condition and fault condition are graphic display in man-machine interface. Configuration testing unit according to customer requirements. -

Level detection machine X