- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

🍊 From Orchard to Packaging: Inside a Modern Orange Juice Production Line

5/6/2025 7:18:43 PM🍊 From Orchard to Packaging: Inside a Modern Orange Juice Production Line

The taste of freshly squeezed orange juice—sweet, tangy, and bursting with natural goodness—is something consumers around the world love. Behind every bottle, carton, or can of orange juice lies a highly sophisticated production line that transforms raw citrus fruit into shelf-stable, hygienic, and attractively packaged beverages.

Today, juice manufacturers must balance quality, speed, safety, and flexibility. Whether bottling in glass, Tetra Pak, or aluminum cans, a fully automated orange juice production line ensures consistent product taste and long shelf life while keeping operations efficient and scalable.

Let’s explore the full process—from fresh fruit intake to three types of final packaging—highlighting the equipment and technology that power a state-of-the-art juice plant.

🌾 1. Fruit Receiving & Washing

The journey starts with crates of fresh oranges arriving at the facility.

Equipment Used:

-

Fruit Elevator & Conveyor

-

Rotary Drum Washer

-

Brush Washing Machine

These machines remove dust, debris, and pesticides from the orange skins. Clean fruit ensures that the juice extraction process maintains high hygiene standards.

🍊 2. Juice Extraction

Next, the clean oranges are automatically sorted and fed into juice extraction equipment.

Equipment Used:

-

Orange Grading Machine

-

Automatic Juice Extractor (with reamer-type or press-type mechanisms)

-

Peel Separator

-

Juice Screen Filter

💡 Key Machine Highlight: Juice Extractor

This machine uses gentle but powerful squeezing mechanisms to extract juice without crushing the bitter rind or seeds—ensuring better taste.

Pulp and seeds are filtered out, and the juice is passed to the next stage for further treatment.

🌡️ 3. Enzymatic Treatment & Filtration

Orange juice often contains pulp and natural cloudiness. To ensure clarity and consistency (especially for glass bottles or cartons), enzymes may be added.

Equipment Used:

-

Enzyme Dosing System

-

Preheating Tank

-

Vacuum Belt Filter / Centrifuge

After enzymatic treatment, the juice undergoes fine filtration to remove any remaining solid particles.

❄️ 4. Pasteurization – Preserving Freshness

To extend shelf life while preserving flavor and nutrients, the juice is heat-treated.

Equipment Used:

-

Plate-type or Tubular Pasteurizer

-

Holding Tube (for flash pasteurization)

-

Hot Water Generator

💡 Key Machine Highlight: Flash Pasteurizer

This system heats juice to 90–95°C for 15–30 seconds and rapidly cools it. It kills microbes while preserving vitamins and flavor.

🧊 5. Homogenization & Deaeration (Optional)

To improve product stability and mouthfeel, juice can be homogenized under high pressure. Deaeration removes oxygen, which can cause oxidation and spoilage.

Equipment Used:

-

Homogenizer

-

Vacuum Deaerator

This stage is especially important for Tetra Pak and glass bottle packaging where shelf stability is crucial.

🛢️ 6. Blending & Storage

At this stage, juice concentrate, natural flavorings, or sugar syrup may be added depending on the recipe.

Equipment Used:

-

Batch Blending Tank with Agitator

-

Sugar Dissolving System

-

Storage Tank (Jacketed with Cooling)

💧 7. Aseptic or Sterile Filling: Packaging Flexibility

Now the juice is ready to be packed—and here’s where automation and flexibility shine. A single production facility can adapt to multiple formats:

🥫 A. Canned Orange Juice (Aluminum Cans)

Ideal for mass-market, short shelf-life distribution.

Equipment Used:

-

Can Rinser

-

Hot-Fill Can Juice Filling Machine

-

Steam Jet Cap Sterilizer

-

Can Seamer

-

Tunnel Pasteurizer

💡 Key Machine Highlight: Juice Hot Filling Machine for Cans

Ensures juice is filled at high temperatures (~85°C) to maintain sterility before sealing.

📦 B. Tetra Pak (Aseptic Brick Pack)

Perfect for long shelf life and ambient storage.

Equipment Used:

-

Aseptic Tank

-

Tetra Pak Aseptic Filling Machine

-

UV Sterilization Tunnel for Packaging Film

💡 Key Machine Highlight: Tetra Pak Aseptic Filler

Fills juice in sterile environments with zero oxygen exposure, locking in freshness for up to 12 months without preservatives.

🍾 C. Glass Bottle Packaging

Popular for premium juice products in cafés and supermarkets.

Equipment Used:

-

Glass Bottle Rinser

-

Hot Fill Glass Bottle Juice Filling Machine

-

Capper (Twist or Lug Cap)

-

Tunnel Pasteurizer or Retort Sterilizer

-

Bottle Dryer

💡 Key Machine Highlight: Hot Fill Bottle Filler

Ensures vacuum-sealed closure immediately after filling at high temperature to avoid contamination.

🧪 8. Inspection & Quality Control

Regardless of packaging, every filled product passes through strict quality control.

Equipment Used:

-

Fill Level Detector

-

Leak Tester

-

Metal Detector

-

Date Code Printer

Advanced sensors ensure that every can, carton, or bottle meets safety and packaging standards.

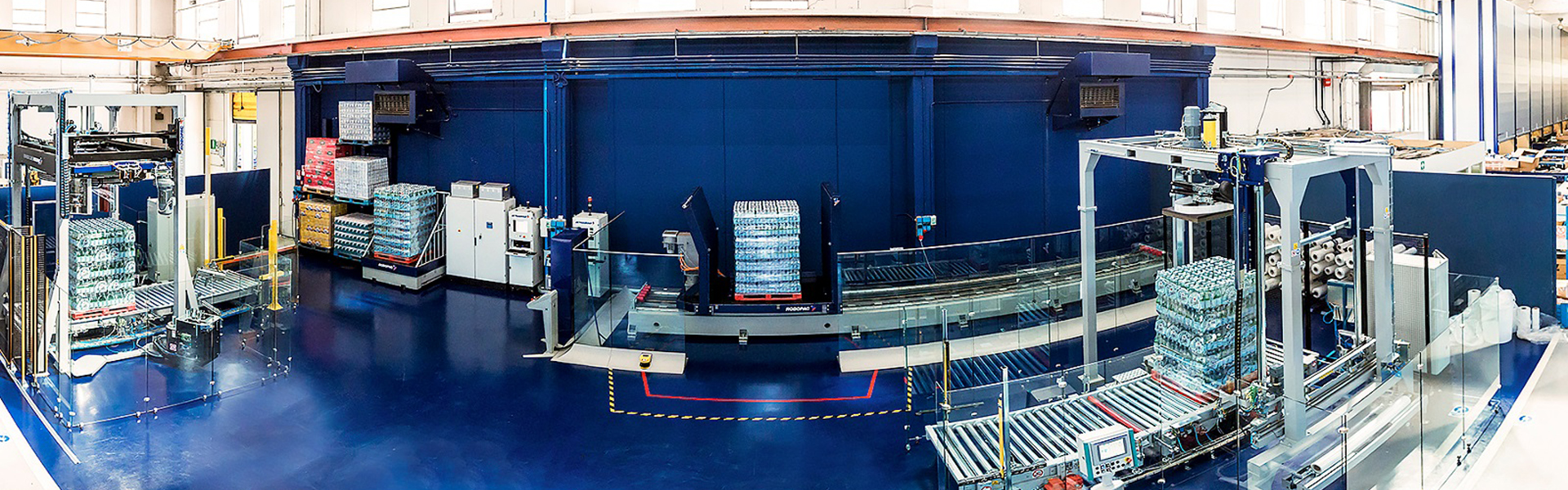

📦 9. Secondary Packaging & Palletizing

Final products are grouped, wrapped, and prepared for shipment.

Equipment Used:

-

Shrink Wrapper / Wrap-around Cartoner

-

Automatic Case Packer

-

Robotic Palletizer

-

Pallet Stretch Wrapper

🚀 Why Invest in a Flexible Orange Juice Production Line?

| Feature | Benefit |

|---|---|

| Multi-Format Packaging | Serve diverse markets and retailers |

| Automation | Minimize labor and human error |

| Product Quality | Consistent flavor, color, and shelf life |

| Hygiene Control | Food-grade materials + CIP systems |

| Production Speed | Up to 24,000 bottles or 36,000 cartons per hour |