- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

🐾 Feeding Quality with Precision: Inside a Modern Pet Food Can Production Line

5/6/2025 7:24:54 PM🐕 1. Raw Material Receiving & Pre-processing

The process begins with the arrival of fresh or frozen meat, grains, vegetables, and supplements.

Equipment Used:

-

Frozen Block Crusher

-

Meat Grinder / Pre-breaker

-

Mixer & Homogenizer

-

Silo Feeders for Dry Ingredients

💡 Key Machine Highlight: Frozen Block Crusher

This heavy-duty machine breaks frozen meat or by-product blocks into manageable chunks for further grinding, crucial for high-volume processing.

🔬 2. Recipe Mixing & Formulation

All ingredients—meats, fats, starches, vitamins, and minerals—are blended according to a strict recipe. The aim is a uniform slurry or pate texture, depending on the product.

Equipment Used:

-

Vacuum Mixer-Cooker

-

Pre-Conditioner

-

Enzyme Dosing System (Optional)

The mixer is designed to ensure proper emulsification of fats and thorough incorporation of micronutrients. Precise dosing systems guarantee nutritional balance for different pet food formulas (puppy, senior, hypoallergenic, etc.).

🥫 3. Can Filling

Now comes one of the most critical steps—filling the cans. Whether you're making a chunky stew or a pâté-style product, filling accuracy is key.

Equipment Used:

-

Volumetric Piston Filler or Auger Filler

-

Multi-head Weigher (for chunks)

-

Automatic Can Feeder

-

Can Denester

💡 Key Machine Highlight: Volumetric Can Filler

This ensures each can gets the exact weight and texture without air pockets or overflows, which are critical for consistent quality and downstream sterilization.

🧯 4. Vacuum Seaming

Once filled, the cans are automatically transferred to the seaming station. A vacuum or steam injection system removes excess air to reduce oxidation and ensure a strong seal.

Equipment Used:

-

Vacuum Can Seamer

-

Double Seam Inspection Camera

The lids (usually easy-open aluminum tops) are sealed tightly to form a bacteria-proof enclosure before sterilization.

♨️ 5. Sterilization (Retorting)

Unlike human beverages or juices, wet pet food must be shelf-stable for long periods without refrigeration. This requires retort sterilization, a process of pressurized cooking inside the sealed can.

Equipment Used:

-

Steam Retort / Water Spray Retort

-

Rotary Retort (for layered consistency)

-

Retort Shuttle Loader

💡 Key Machine Highlight: Rotary Retort Sterilizer

This equipment allows for continuous sterilization at 121–135°C for 30–90 minutes depending on the product type. Rotary movement ensures uniform heat penetration for meaty chunks or layered products.

❄️ 6. Cooling & Drying

Once sterilized, cans must be rapidly cooled and dried to prevent damage to labels and to prepare for further processing.

Equipment Used:

-

Cooling Tunnel

-

Air Knife Dryer / Can Dryer

-

Conveyor System with Buffering

Cans pass through a cool water shower or spray chamber, then an air blower removes excess moisture before labeling.

🏷️ 7. Labeling & Coding

Each can must now be clearly labeled with product info, ingredients, brand design, and expiry details.

Equipment Used:

-

Wrap-around Labeling Machine

-

Inkjet or Laser Date Coder

-

Barcode Validator

💡 Key Machine Highlight: Automatic Labeler with Smart Sensors

This ensures perfect alignment and adhesion even at high speeds (up to 400 cans/min), while integrated scanners reject misaligned or unlabeled units.

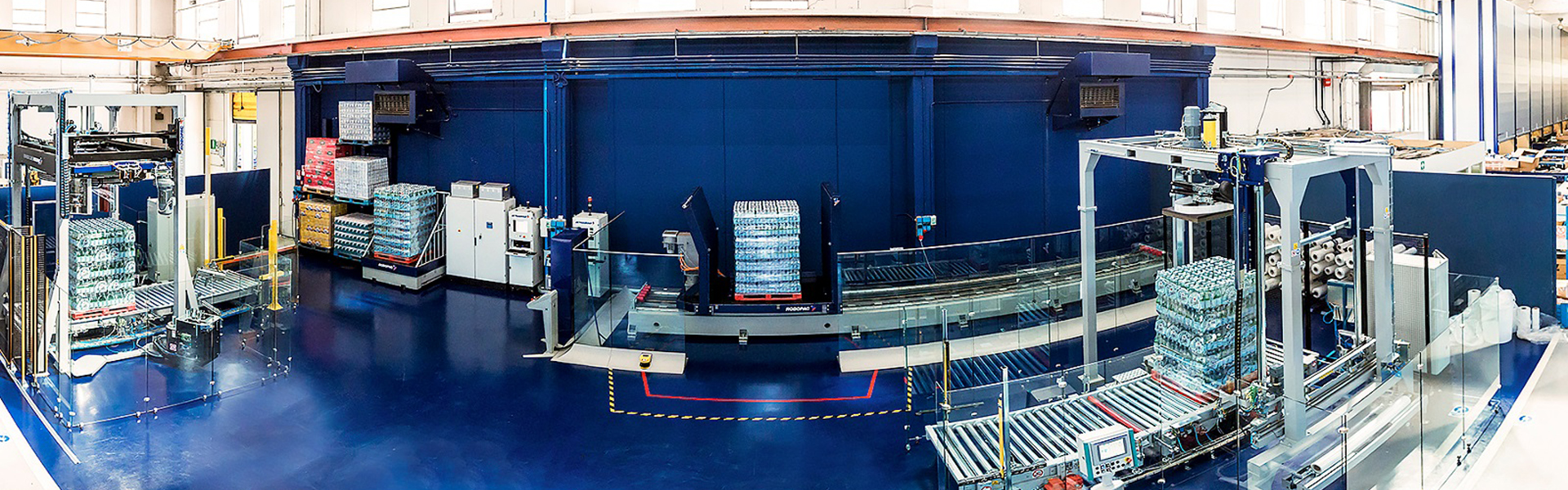

📦 8. Secondary Packaging & Palletizing

Final packaged cans are grouped, wrapped, and palletized for warehouse storage and distribution.

Equipment Used:

-

Can Cartoner / Cluster Packer

-

Shrink Wrap Tunnel

-

Robotic Palletizer

-

Pallet Stretch Wrapper

Boxing is often customized for retail or bulk formats—ranging from 3-pack retail trays to full 24-can shipping cartons.

🧼 9. Cleaning & Hygiene

Hygiene is non-negotiable in pet food manufacturing. All food-contact equipment is CIP-ready (Clean-In-Place), and the entire line complies with HACCP, GMP, and FDA standards.

Sanitation Features:

-

Stainless steel build (SUS304 or SUS316L)

-

No dead zones or manual cleaning required

-

Sanitary piping and quick-disconnect fittings

⚙️ Key Advantages of an Automated Pet Food Can Line

| Feature | Benefit |

|---|---|

| Full Automation | From raw meat to sealed can—minimal manual labor |

| High Throughput | Up to 400–600 cans per minute |

| Nutritional Accuracy | Precision dosing of ingredients and supplements |

| Shelf Stability | Retort sterilization guarantees 12–24 months of shelf life |

| Packaging Flexibility | Easy to adapt to different can sizes and recipes |

| Compliance Ready | Meets food-grade and export hygiene standards |

🐶 Why This Matters to Your Brand

The global pet food market continues to grow rapidly, driven by health-conscious consumers, rising pet ownership, and premium product trends. Whether producing for dogs, cats, or exotic pets, investing in a modern, high-speed pet food canning line ensures:

-

Better quality control

-

Higher production efficiency

-

Long-term cost savings

-

Stronger brand reputation

📦 Final Thoughts: Technology that Tails Wag

From frozen meat to shelf-stable cans, the journey of pet food is powered by innovation, hygiene, and automation. Whether you're an established manufacturer or a startup entering the premium pet food market, a high-quality canning production line helps you meet demand, ensure product safety, and maintain the trust of your most loyal customers—and their four-legged companions. 🐾🥫